An SPC control chart will allow you to track the trend of critical variables in a production environment. It is important that the production engineer understand whether or not changes or variation in the critical variables are natural variations due to the tolerances inherent to the production machinery, or whether or not the variations are due to some systemic, assignable cause that needs to be addressed. If the changes in critical variables are due to the natural variations, then a frequency histogram of the variations will usually follow one of the common continuous (normal, exponential, gamma, Weibull) or discrete (binomial, Poisson, hypergeometric) distributions. It is the job of the SPC engineer to know what distribution best models his process. Periodically plotting of the variation of critical variables will give SPC engineer important information about the current state of the process. A typical frequency histogram looks like the chart below.

Frequency Histogram Chart – 2 (Interactive)

In the pull-down sections below you find descriptions of the Frequency Histogram Chart options. There are two options: Setup and Data. Click on either of the items to see a full description.

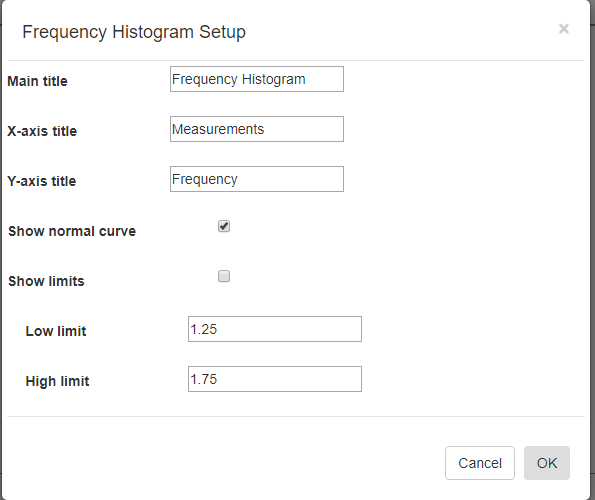

Setup

Main title [Frequency Histogram]-The main title of the chart

X-axis title [Measurements]-The x-axis title

Y-axis title [Frequency]-The y-axis title

Show normal curve [x]– Check to show the normal curve approximation for the data

Show limits [ ]– Check to show limit lines for the chart.

Low limit [1.25]- Specif the low limit value.

High limit [1.75]– Specif the high limit value.

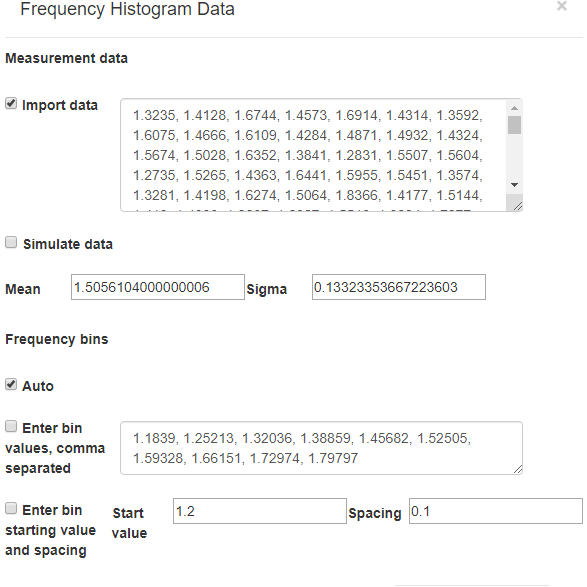

Data

Import data [x]- Check to use data copied into the Import Data field. Enter as comma separated values, or copy data from spreadsheet.

Simulate data [x]-Check and when the dialog is closed, a new set of data (100 values) are generated using the mean and sigma values entered below.

Mean [1.5]– The mean value to use in the data simulation.

Sigma [0.2]– The sigma (standard deviation) to use in the data simulation.

Frequency bins

Auto [x] – The frequency bins are automatically calculated based on the minimum and maximum values of the data.

Enter bin values, comma separated [ ] – check to use the bin values listed to the right. Enter the bin values to in the box to the right.

Enter bin starting value, and spacing [ ] – check to use bin values calculated from the starting value and bin spacing. The maximum bin value is calculated from the maximum in the data.

Start value [1.25] – the starting bin value.

Spacing [ 0.1] – the spacing between adjacent bins.